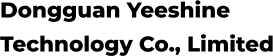

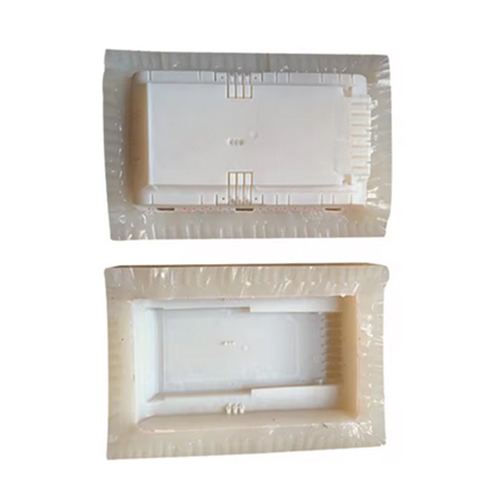

Acrylic ABS Vacuum Molding

0.30 USD ($)/Unit

Product Details:

- Surface Finish Polished

- Usage & Applications Industrial

- Product Type Machine Parts

- Material Plastic

- Color White

- Click to View more

X

Acrylic ABS Vacuum Molding Price And Quantity

- 0.30 USD ($)/Unit

- 10 Unit

Acrylic ABS Vacuum Molding Product Specifications

- White

- Industrial

- Plastic

- Machine Parts

- Polished

Acrylic ABS Vacuum Molding Trade Information

- Cash in Advance (CID)

- 5000 Unit Per Month

- 7-10 Days

Product Description

The Acrylic ABS Vacuum Molding is a high-quality plastic material that is widely used in various industrial applications. The product comes in a polished white surface finish that gives it a sleek and professional look. The material is a combination of Acrylic and ABS, making it highly durable and resistant to wear and tear. It is perfect for manufacturing products that require high impact resistance, such as automotive parts, electronic enclosures, and medical devices. The Acrylic ABS Vacuum Molding is easy to work with, making it an ideal choice for manufacturers, service providers, distributors, and traders who are looking for a reliable and versatile plastic material for their projects.

FAQs of Acrylic ABS Vacuum Molding:

Q: What is the composition of the Acrylic ABS Vacuum Molding?

A: The Acrylic ABS Vacuum Molding is a combination of Acrylic and ABS plastic.Q: What is the surface finish of the Acrylic ABS Vacuum Molding?

A: The Acrylic ABS Vacuum Molding comes in a polished white surface finish.Q: What are the industrial applications of the Acrylic ABS Vacuum Molding?

A: The Acrylic ABS Vacuum Molding is widely used in various industrial applications, including automotive parts, electronic enclosures, and medical devices.Q: Is the Acrylic ABS Vacuum Molding durable?

A: Yes, the Acrylic ABS Vacuum Molding is highly durable and resistant to wear and tear.Q: Who can use the Acrylic ABS Vacuum Molding?

A: The Acrylic ABS Vacuum Molding is perfect for manufacturers, service providers, distributors, and traders who are looking for a reliable and versatile plastic material for their projects.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Vacuum Casting Prototype Machine Parts' category

Back to top